Featured Products

Featured Projects

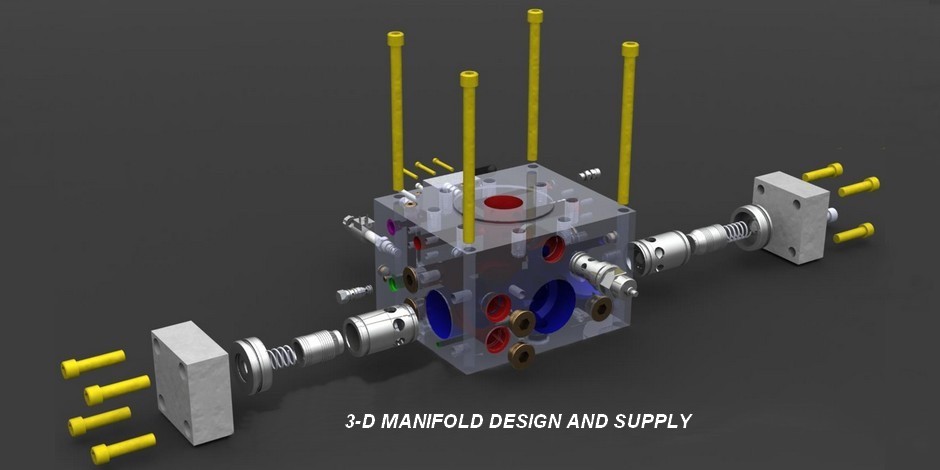

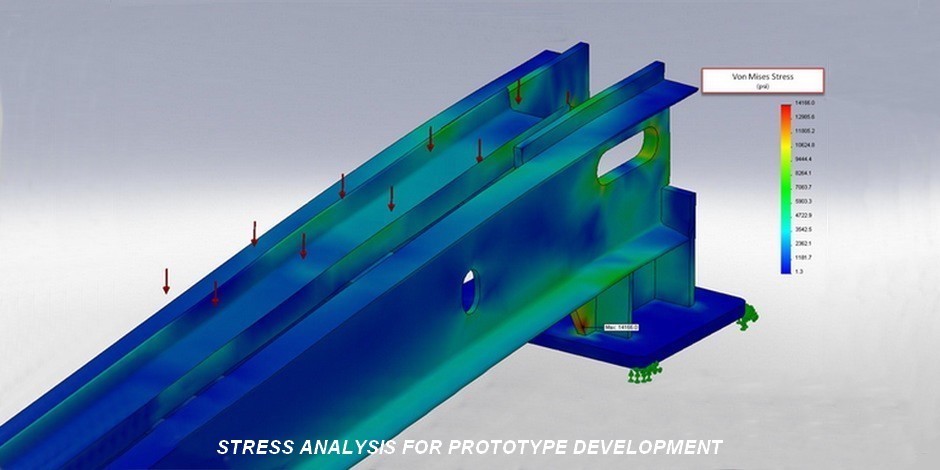

EngineeringSawyer Systems technical experience and professional engineers are the foundation of our products and services. Our staff of fluid power engineers analyze customer requirements and apply the concepts of "Value Engineering" to determine a recommended course of action. Services include: hydraulic system sizing, preparing P. & I.D. drawings, hydraulic and electrical schematics, hydraulic manifold design, 3D power unit physical layout drawings, and 3D pipe installation layouts. The engineering group is also responsible for preparing the technical documentation for pressure and flushing tests, factory acceptance testing and the instruction sets, diagrams and operational text for our comprehensive owners manuals. |

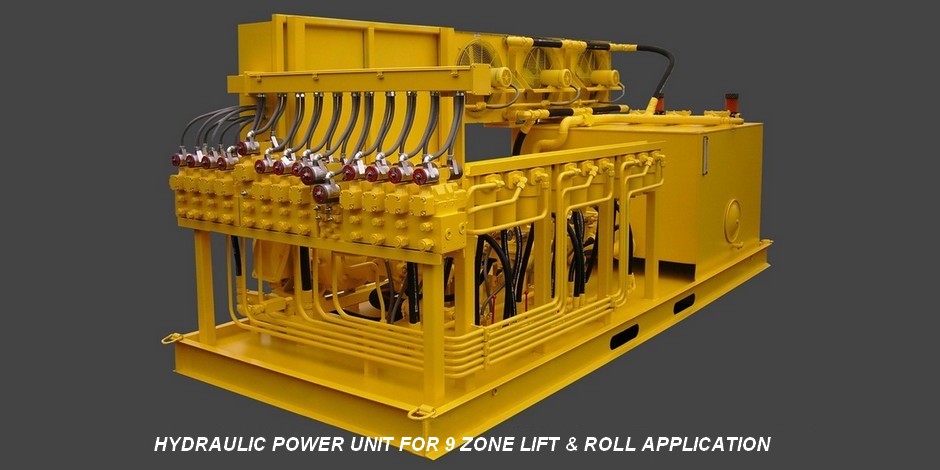

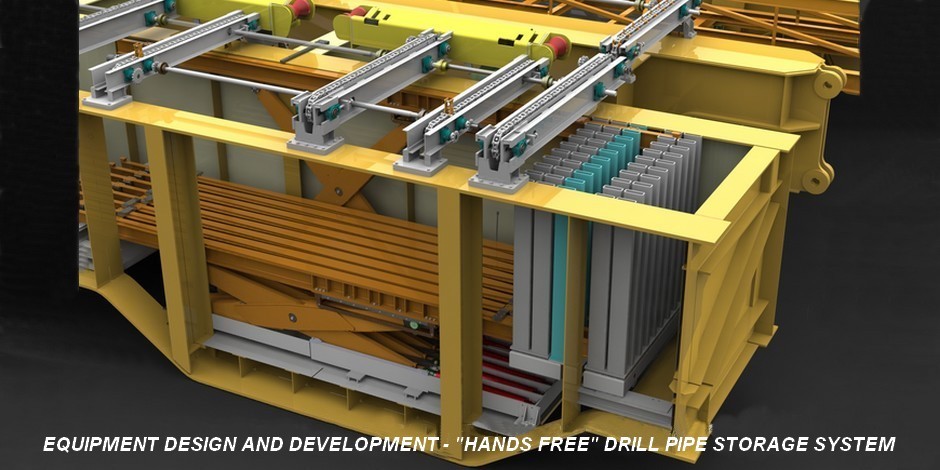

FabricationThe quality of our product begins with the quality of our craftsmen. Our senior fabricators have over 20 years of experience in building the highest quality hydraulic power units in the industry. Our power units are designed specifically for each application, optimizing the layout for the field piping installation and future maintenance. In addition to hydraulic power units, we also fabricate custom operators valve panels, direct hydraulic drive winches, constant tension winches (Tag-Lines), and prototype equipment. Our UL-508 certified panel shop fabricates the controls panels large and small for all hydraulic power units and the specialized equipment we provide. All equipment is designed and built in compliance with our QA/QC requirements. We provide all material test reports (MTR’s), calibration certificates, welder qualifications and certificates of conformance.

|

InstallationSawyer Systems offers complete installation services for hydraulic systems and inter-connecting piping. An on-site project manager is assigned to oversee product installation and to provide the daily communication between the customer and other contractors. Two complete 40-foot mobile shops are available for on-site equipment and inventory support. The shops contain all welding , bending, and hose making equipment required for each project. A complete installation includes on-site and shop fabricated pipe spools, design and fabrication of pipe supports, installation of the pipe and hose assemblies, flushing, pressure testing, and QA/QC documentation to commission each line. |