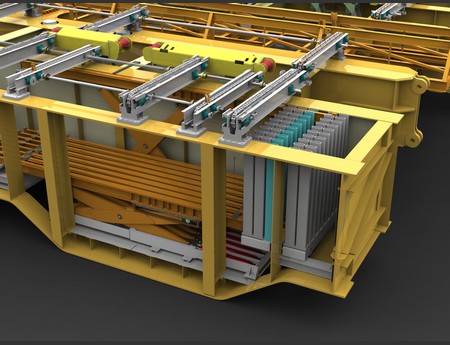

Pipe Storage System

Error message

- Deprecated function: The each() function is deprecated. This message will be suppressed on further calls in _menu_load_objects() (line 579 of /home2/hydraul5/public_html/includes/menu.inc).

- Deprecated function: implode(): Passing glue string after array is deprecated. Swap the parameters in drupal_get_feeds() (line 394 of /home2/hydraul5/public_html/includes/common.inc).

Sawyer Systems has developed and is in the Patent Pending phase of a mechanized drill pipe storage system. This system can be adapted for any size tubular. The first prodcution system is installed on an Arctic Style drilling rig and has been in constant operation since 2010.

The system allows the drill pipe to be removed from the drill floor and stored on the rig without any rig hands touching the pipe. Storing the pipe on the rig also saves the time of removing the drill string form the rig, storing it in racks, separately transporting it to the next drill site and then re-inserting it back onto the rig. This first system stores 12,000 feet of 4” drill pipe in 32 foot or 64 foot long joints (doubles).

The picture on the right shows an open view of the system. The pipe is stored below the floor in vertical columns. A scissor lift under each column raises or lowers the drill pipe one diameter to accept the new pipe or present the stored pipe back to the rig for use. A horizontal conveyor is used to roll the pipe to or from the desired slot, the upper conveyor roll pipe over the top of the system if it is not to be stored. Pipe lift conveyors lift or lower the drill pipe from the floor level to the top of the storage level. The pipe is stored in a Last-In, First-Out arrangement keeping the drill string in the same order time after time. Since the drill pipe is stored below the floor, the floor can be used to transport specialty joints, tools or casing into the drill rig at the floor level.

The example pictures below show more details of the system and gives further description as to the operation.