Engineering

Error message

- Deprecated function: The each() function is deprecated. This message will be suppressed on further calls in _menu_load_objects() (line 579 of /home2/hydraul5/public_html/includes/menu.inc).

- Notice: Trying to access array offset on value of type int in element_children() (line 6542 of /home2/hydraul5/public_html/includes/common.inc).

- Notice: Trying to access array offset on value of type int in element_children() (line 6542 of /home2/hydraul5/public_html/includes/common.inc).

- Notice: Trying to access array offset on value of type int in element_children() (line 6542 of /home2/hydraul5/public_html/includes/common.inc).

- Notice: Trying to access array offset on value of type int in element_children() (line 6542 of /home2/hydraul5/public_html/includes/common.inc).

- Notice: Trying to access array offset on value of type int in element_children() (line 6542 of /home2/hydraul5/public_html/includes/common.inc).

- Notice: Trying to access array offset on value of type int in element_children() (line 6542 of /home2/hydraul5/public_html/includes/common.inc).

- Notice: Trying to access array offset on value of type int in element_children() (line 6542 of /home2/hydraul5/public_html/includes/common.inc).

- Notice: Trying to access array offset on value of type int in element_children() (line 6542 of /home2/hydraul5/public_html/includes/common.inc).

- Deprecated function: implode(): Passing glue string after array is deprecated. Swap the parameters in drupal_get_feeds() (line 394 of /home2/hydraul5/public_html/includes/common.inc).

Our reputation for success originates from the quality of the engineering staff.

With over 50 years combined hands-on experience, our Professional Mechanical Engineer’s, Fluid Power and Control Engineers utilize the latest AutoCAD, Inventor, Solid Works and Automation Studio products to develop each application exceeding our clients expectations.

Our engineers have developed over 2,000 hydraulic systems ranging from fractional to over 5,000 horsepower. Our systems are in installed in all applications from open pit mines to hospital clean rooms. From simple open loop systems to hydrostatic drives to the most sophisticated servo controlled motion platforms, we have designed, manufactured, installed and maintained successful systems worldwide.

While the majority of the engineering effort is dedicated to developing our in-house systems, we frequently supply Consulting Services for our customers. Our engineers can be tasked for developing user demand graphs, procurement specifications, Manufacturing and Installation Standards, as-built drawings and hydraulic system optimization with Automation Studio.

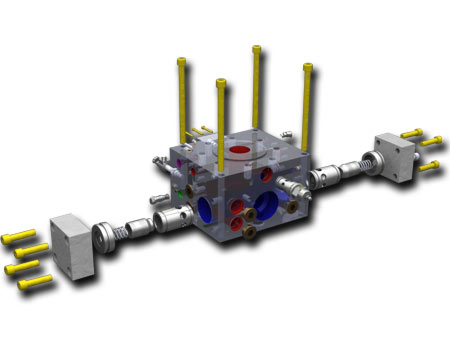

A Hydraulic Manifold is a component regulating fluid flow between pumps & actuators and other components. Sawyer Systems has built a reputation upon the superior engineering and unbeatable reliability of our manifold solutions. As a result, our hydraulic manifolds are in use worldwide for a wide variety of applications. Our understanding of manifold design and manufacturing has allowed us to incorporate many essential advantages such as reduced size, weight, and cost. Our high quality and reliable systems provide a clean and leak free solution to our customers’ most challenging control system problems.

Utilizing 3D Inventor® and Solidworks® software, our engineering staff has been very successful supplying pre-engineered and shop manufactured hydraulic piping systems. These systems with over 6,000 lineal feet of pipe have shipped to the job-site and installed with a bolt in place hydraulic piping system. For other systems, the engineering staff provides 3D renderings of piping systems for our on-site installation staff to aide in routing approval and increases their productivity.

Our in-house control systems team designs, manufactures, tests and installs PC based, PLC based and analog controls for the hydraulic systems we provide. The success of each control system is increased by the acceptance of the Human Machine Interface (HMI) by the project’s new operators. Our systems team plans each HMI with the new operators in mind and includes feedback from the operators in the final design. Each PLC, PC or Analog control system is design and assembled to the latest UL-508 standards.

Each project is not complete until the technical documentation is released. This includes the as-built drawings, the quality control documents, and the owner’s manuals. Our owner’s manuals provide complete manufacturers data and photographs showing adjustment locations.